Warehouse logistics management system

Introduction.

This system mainly solves the rea-time colection of finished product outbound and inbound data, and generates reports of non-delayed inventory torreference by relevant managers of the enterprise; automaticaly guides oading vehicdles, outbound forkift drivers, and loading personnel to load and reduceDelivery staff, orderly, efficient and accurate delivery.

Scope of application 1.Accurately count the packaging materials loaded by the loading conveyor belt and upload the quantity and species to the relevant management software. 2.Accurately count the finished products on the production line, and upload the relevant numbers to the management software.

Categories:

Product description

Finished goods logistics and inventory information management system

SystematicFunction & Features

Collect the warehouse data from time to time, and generate the report of no delay inventory data.

Automatically guide vehicles to load according to the order ofinvoicing, no personnel guidance is required.

Loadinginformation is automatically sent to the loading terminal and the forklift driver.

Automatically generate a position intoation report, showing the variety, production date (batch),and quantity of each position stacked.

Position map guide, mark the idle status and stacking amount ofthe position with different colors.

Accurately count the number ofoutbound stock to avoid the problem of more installations and less installations.

Can communicate with the management software currently used by enterprises, and exchange data.

Finished Product Online Moisture Detection ControlSystem+

Keywords:

Warehouse logistics management system

Previous

Previous

next

Related Products

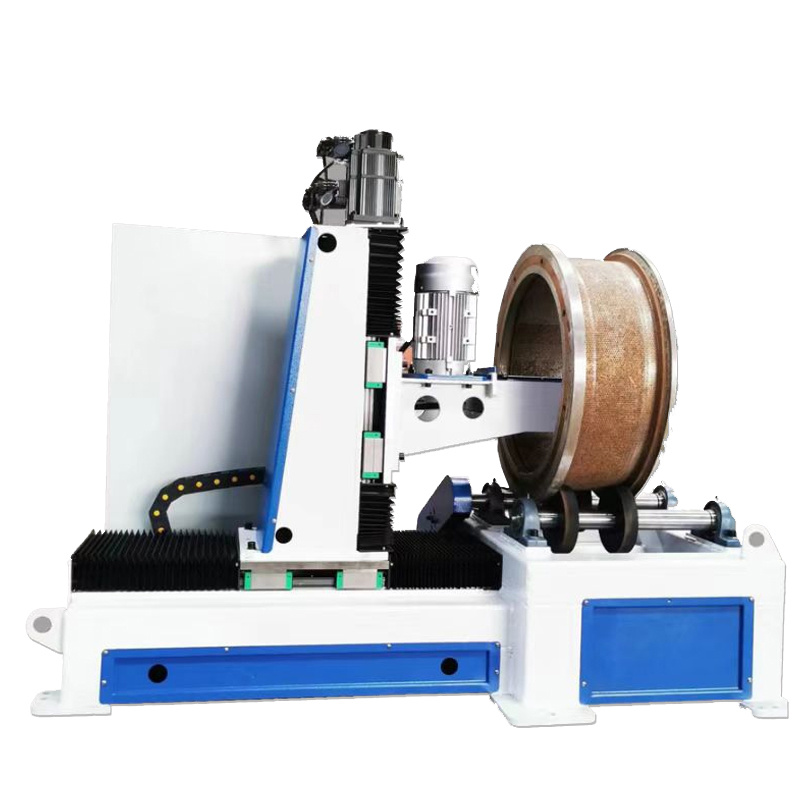

Ring milling chamfering counterboring integrated machine

CNC Refurbishing machine for maintenance on ring die

CNC Refurbishing machine for maintenance on ring die

Online Message