Closed-cycle dryer gas & waste heat recovery unit

Applicable scenarios:

- Raw material drying in feed production

- Other industries requiring large-scale drying equipment, such as chemical, building materials, and food industries

Scope of application 1.Accurately count the packaging materials loaded by the loading conveyor belt and upload the quantity and species to the relevant management software. 2.Accurately count the finished products on the production line, and upload the relevant numbers to the management software.

Categories:

Product description

3.Efficient Circulation, Continuous Supply

Each unit can return to the dryer per hour22tons ofdry gas at a temperature of 80-95℃ and a relative humidity of about 8%, ensuring the continuous and efficient operation of the dryer and improving productionefficiency.

4.Intelligent Operation, Stable and Reliable

This unit uses advanced algorithms and can automatically sense the dryer startup and automatically operate, with a high degree of intelligence. Since itsintroduction, it has been stably operating in high-end feed production enterprises in China for nearly two years, saving enterprises a large amount of energy costs and creating good economic benefits.

Product Advantages:

1.Environmentally Compliant: Closed-loop circulation of exhaust gas, zero emissions, easily meets environmental requirements.

2.Energy Saving and Cost Reduction: Waste heat recovery technology significantly reduces energy consumption and saves operating costs.

3.High Efficiency and Stability: Continuous supply of high-temperature dry gas improves production efficiency.

4.Intelligent Operation: Supported by advanced algorithms, automatic sensing, automatic operation, and simple operation.

5.Patented Technology: Independently developed, technologically advanced, and reliable quality.

Successful Cases:

This unit has been put into use in high-end feed production enterprises in China for nearly two years, with stable operation, high degree of intelligence, and advanced algorithms. It automatically senses dryer startup and automatically operates. Since its introduction, it has saved enterprises a large amount of energy costs and created good economic benefits.

Keywords:

Closed-cycle dryer gas & waste heat recovery unit

Related Products

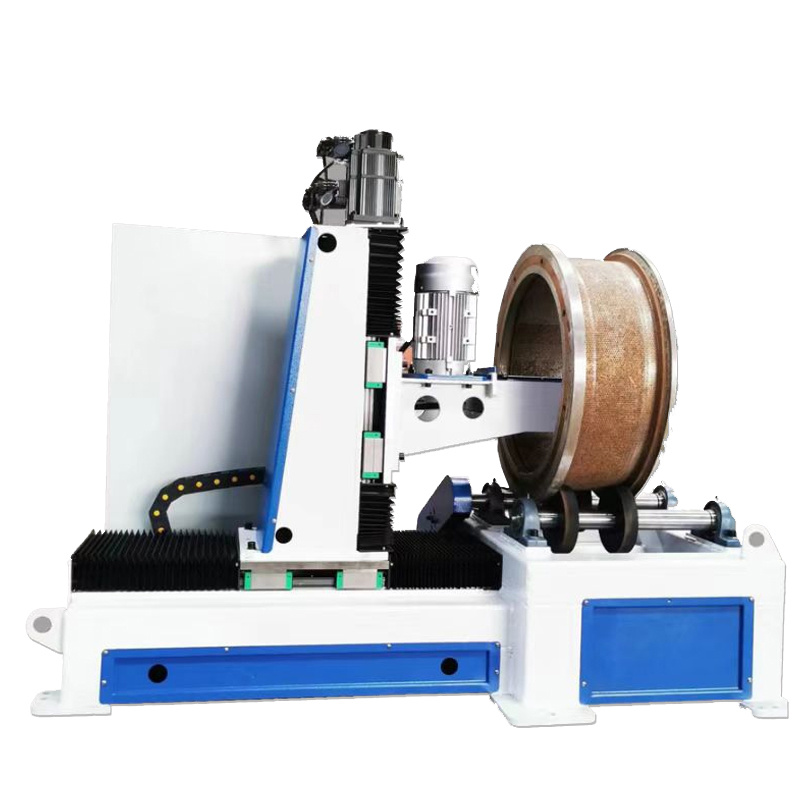

Ring milling chamfering counterboring integrated machine

CNC Refurbishing machine for maintenance on ring die

CNC Refurbishing machine for maintenance on ring die

Online Message